-40%

Torque Arm Mount Kit - Hiltsy TA Mount for Ford 8.8 in 4th Gen F-Body

$ 35.89

- Description

- Size Guide

Description

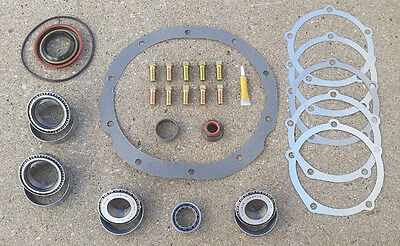

You are looking at a kit that allows you to modify a Ford 8.8 differential housing to include a torque arm mount so that the rear can be used in a 3rd or 4th Generation GM F-Body (1982-2002 Camaro / Firebird). This is a huge step up from the factory GM 10-bolt rear with its 7.5" ring gear. Nothing in this kit is welded, it's just the pre-engineered materials you need to build your own TA Mount. You have to weld the TA mount pieces together and then fit & weld / bolt the mount to your 8.8 housing. Welding the finished mount to the nodular iron housing requires some special welding materials (nickel rod or wire - not included), welding techniques, pre-heating, and post-heating to make the welds effective (see details below). The 10 individual plates in the kit are uniquely shaped to fit the 8.8 housing with a minimum amount of trimming. They are laser or plasma cut and include mounting holes for attaching the torque arm and for the 3-hole rib on the 8.8 housing. This kit is designed for the 1995-2002 Ford Explorer 8.8 (pictured) and also the Ranger 8.8 with the 3-bolt pinion rib on the passenger-side of the housing. The kit may also fit other 8.8 housings such as the F-150. I've been asked several times if my mount will fit or could be modified to fit a Fox-body / Mustang 8.8 housing, but I've never tried it myself or know of anyone that has made it work. The detailed instruction sheet provided shows how to build & weld the mount which is pretty easy if you have some basic fabrication skills.Here is some more detail on welding: A critical step when installing a weld-on mount for the 8.8 is the welding process & materials you have to use to make the welds sound between the mount and the housing. The 8.8 housing is cast from ductile iron or nodular iron and if you do a Google search you'll find a lot of good reading on welding this material. Basically you have to use nickel welding rod or wire, and pre-heat and post-heat the welded area of the casting. You'll find nickel wire/rod isn't cheap but if you weld it using regular MIG wire the welds will look great but will be brittle and may even crack at the joint while cooling. Even with nickel wire you have to keep heating after welding and find a way to let the housing cool slowly. Proper welding techniques are important! Please note that the pieces included in the TA mount kit are made from A36 (mild steel) so conventional MIG or stick welding can be used when assembling the mount.

With this TA Mount Kit installed the 8.8 will bolt up the stock GM or aftermarket Torque Arm. Re-location of the oil-fill hole in the 8.8 housing is usually required since the factory oil-fill hole is positioned on the driver's side of the housing where the TA Mount is installed (instructions for this are included). Some minor grinding of the 8.8 housing is also required to make the mount fit. This kit has been used successfully on hundreds of 8.8 conversions for the street, drag racing, and road racing. Build details can be found by searching several popular LS1 internet forums.

The kit includes: (10) laser / plasma cut plates uniquely shaped to form the TA Mount, (2) tubes that support the mount (the TA bolts pass through these), and a detailed instruction sheet. This listing is for 1 kit.

This is the original Hiltsy TA Mount Kit, designed by me, with parts made in the U.S.A.